|

|

#1

|

||||

|

||||

|

Hi everyone! My name is Zee and I'm a newbie in the SW hobby. I've kept many freshwater tanks over the past 4 years and now I've decided to move on to Saltwater.

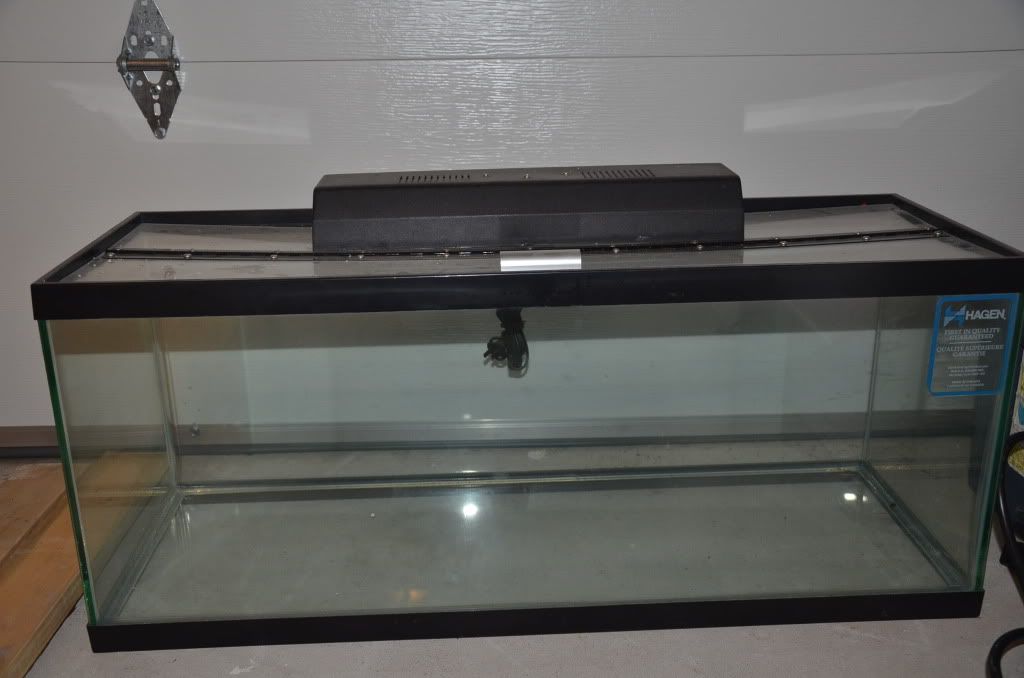

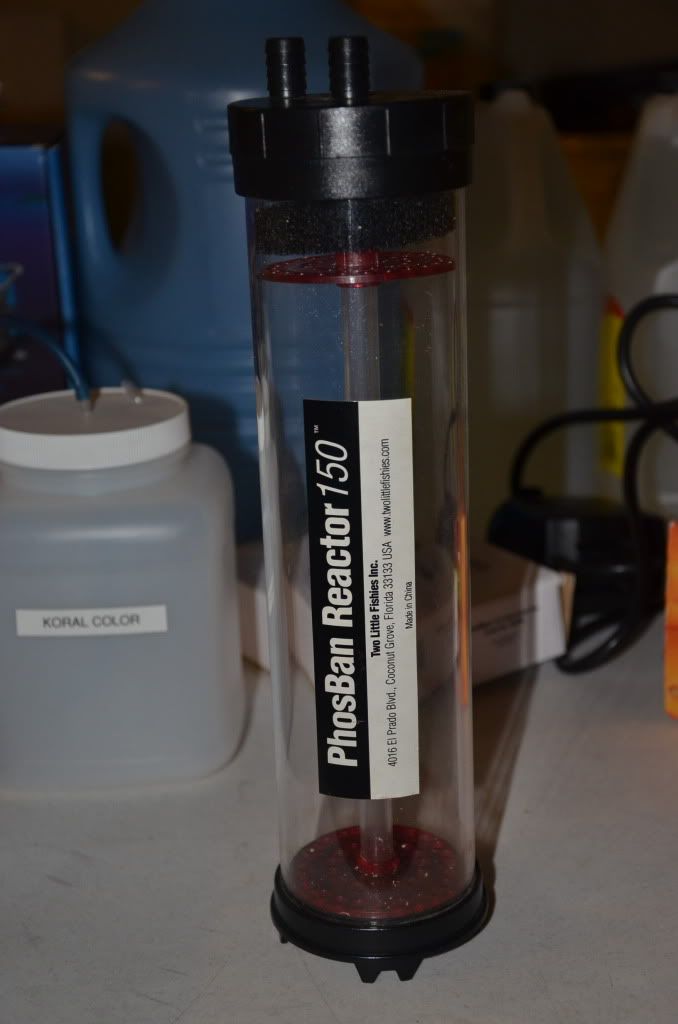

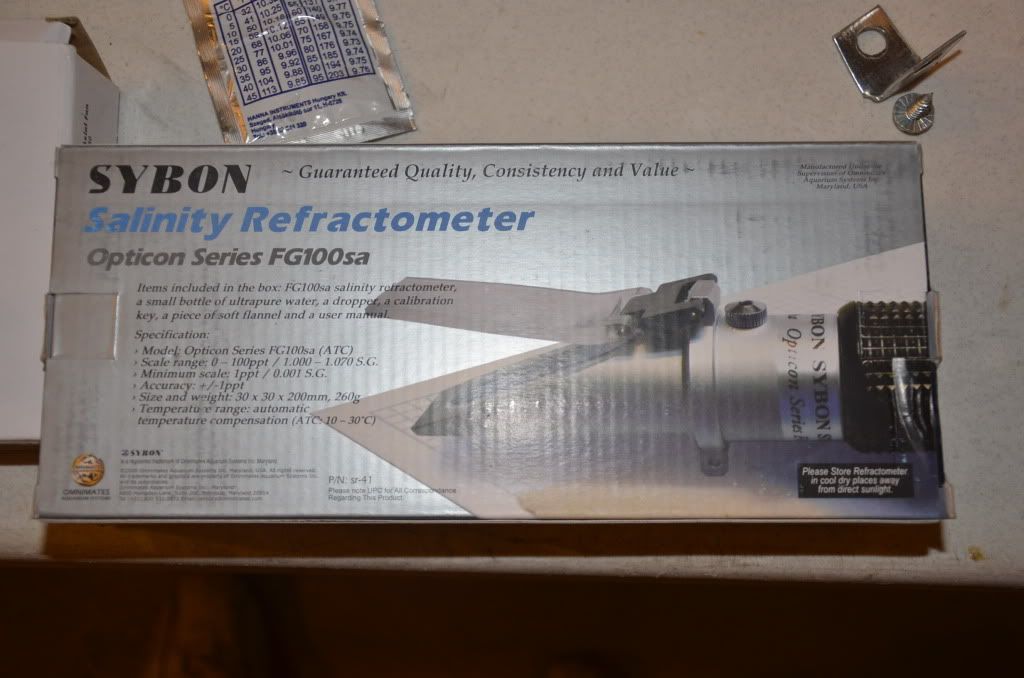

I'm planning on setting up a reef tank. I've been reading a lot of articles over the past few weeks and learning about how to start things up the right way to ensure success in the long run! Biggest lesson learned so far: PATIENCE WILL GET YOU THERE ONE DAY!! Enough talking... Now lets get to the point. I picked up a used setup from Craigslist in the beginning of the year and was wanting to set it up at the time but things didn't work out and it just sat in my house. Now I've gained momentum again and hopefully will carry the torch through. So, the equipment. Tank: Custom ELOS Tank (36" W x 22" H x 20" D) - Rimless Starphire Glass   Stand: The stand this tank came with is not tall enough for my liking it does not have enough space inside for a decent sump. I’ve decided to build a custom stand out of ¾” plywood after being inspired by sphelps’s stand for his 100gal build. I’m building a 48” W x 24” D x 40” H stand. The reason why its that size is because I’ll have ample space for everthing down below and I want to upgrage to a 4’x2’x2’ (120gallon) tank in the future so I can use the same stand. Lighting: 2 x LumenMax Elite Reflectors, 250W Metal Halide Ballasts, 250W 20K Radium Bulbs 2 x T5 Actinics These are currently installed in the Vented Canopy. Yes, the guy was using a canopy over this tank  Here is where I’m a little confused. I want to upgrade to LED lighting. However, I don’t want to dish out the cash as of rightnow… So I’m thinking of using 1 of the MH pendants for now coupled with the Actinics T5s. Would it be okay to use that light for softies? I want corals in the tank but don’t want to kill them with too much light. Filteration: This setup did not come with a sump so I have to build that from scratch. I have a 30gallon tank (36” W x 16” H x 12” D) that I’m thinking of making into a sump.  I’m planning a 3 chamber sump. First for skimmer also the filter sock will be here too. Second for refugium with DSB and Chateo followed by bubble breaker and return chamber. Also, will be hooking up the TLF Phosphate Media Reactor 150  I also have a 9W Coralife UV Steralizer. Will I need this for this setup? Or will it help me at all to keep Algae away?  Skimmer: Warner Marine AS150 Skimmer  Return Pump: Iwaki 30 RT Pump  This is an external pump so I still have to see if I can use this or maybe sell this and buy an Eheim return pump. Water Movement: Vortech MP20 unit & controller  I also have two Tunze Power Heads and a Koralia 4 to supplement the vortech.  Other equipment: Spectra Pure 4-Stage RO/DI System  Vertex Calcium Reactor, complete with CO2 bottle, regulator/solenoid and pH probe - I might sell this and just keep the dosing unit. Haven't decided yet.  Profilux 3 Channel Doser and three containers for supplements  Digital Aquatics ReefKeeper2 with powerstrips, PH probe, temp Probe and other stuff.    Tunze ATO Osmolator  A series of test kits (Elos), salt, supplements   Refractometer  So this is all I have at the moment. I'll be building the stand this sunday hopefully and will start working on the sump sometime during next week. I'll post the dimensions for the stand to have them double checks by the pro DIYers! I want to hear your ideas and suggestions. I'm in the learning phase of the hobby so any help is highly appreciated. Thanks for looking! Last edited by zhasan; 10-20-2012 at 10:17 AM. |