|

|

#1

|

||||

|

||||

|

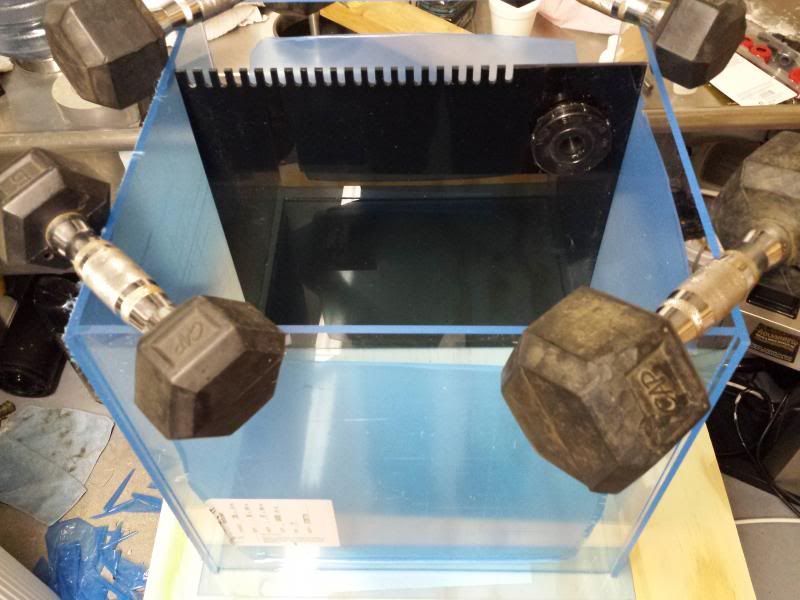

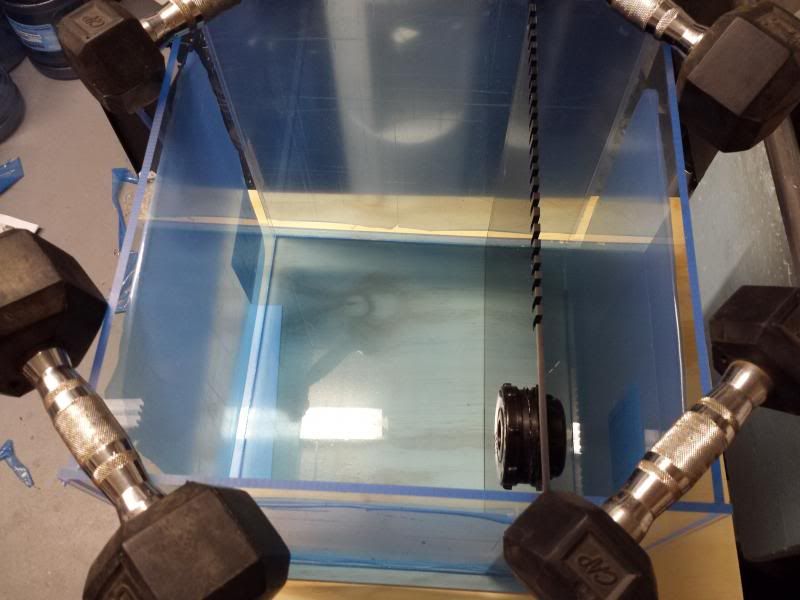

Last weekend i decided that the wifes 5g hex was looking a little small for her clowns. So i picked up some acrylic and here is what happened (i thought i took more pictures along the way but all i really got is as i was putting last side and bottom on.

Side going on:  bottom on:   Trimming off excess:

__________________

Nick Last edited by nrosdal; 11-19-2013 at 05:32 AM. |

|

#2

|

||||

|

||||

|

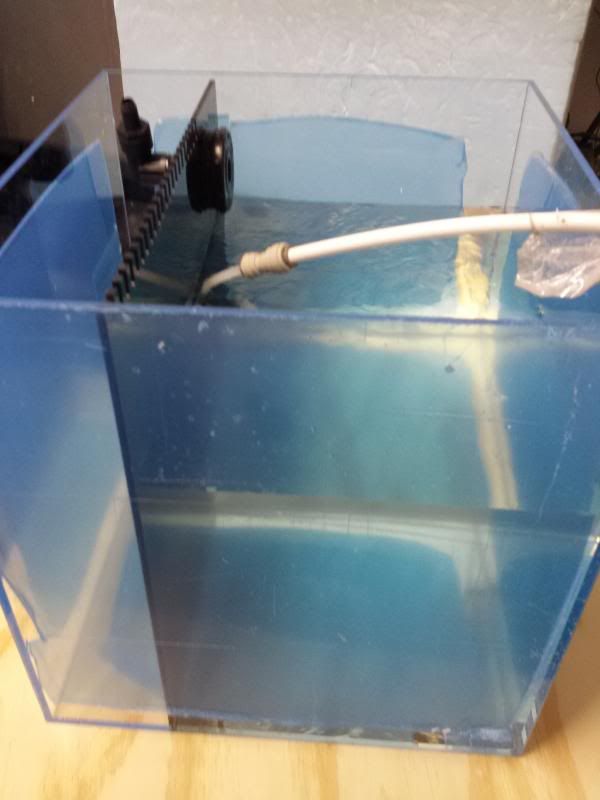

Water Testing:

Polished up edges and built a base for it to sit on:  Mounted gooseneck and par led light:  Plumbed in a little eheim pump:  Here it is now:   Still have to add a top to the back chamber to clean up the cords and help with evap.

__________________

Nick |

|

#3

|

||||

|

||||

|

Looks great job, love following your build, your wife would thank you for it and so will the clowns. Regards Ken

|

|

#4

|

|||||

|

|||||

|

Wow that's some great craftsmanship. If I knew how to build tanks like that and of that quality my house would be full of them!

|

|

#5

|

||||

|

||||

|

Nick,

Very NICE! Does the bearing on the router bit scratch the acrylic during the cleanup process? |

|

#6

|

||||

|

||||

|

Gonna come see this bad boy sometime this week! Don't you appreciate how I invite myself over?

__________________

Mark...  290g Peninsula Display, 425g total volume. Setup Jan 2013. |

|

#7

|

||||

|

||||

|

Thanks all for the kind words. I am quite happy with how it came out.

Quote:

No, the bearing for the most part is stationary once against the material and even if it spins a bit i have not had any issues with scuffs on material as there is quite a bit of sanding and polishing after trimming anyway.

__________________

Nick |

|

#8

|

||||

|

||||

|

Look forward to it. I will do my best to create a dirty job that i need a hand with before you come.

__________________

Nick |

|

#9

|

|||||

|

|||||

|

Did you use Weldon or methylene chloride?

__________________

Guide to building super awesome rock structures / my tank journal http://www.canreef.com/vbulletin/sho...d.php?t=116410 |

|

#10

|

||||

|

||||

|

I had been using MC for quite a while but used weld on 3 for this and didn't notice much difference in consistency or bonding time/quality.

__________________

Nick |