|

|

#3

|

||||

|

||||

|

Quote:

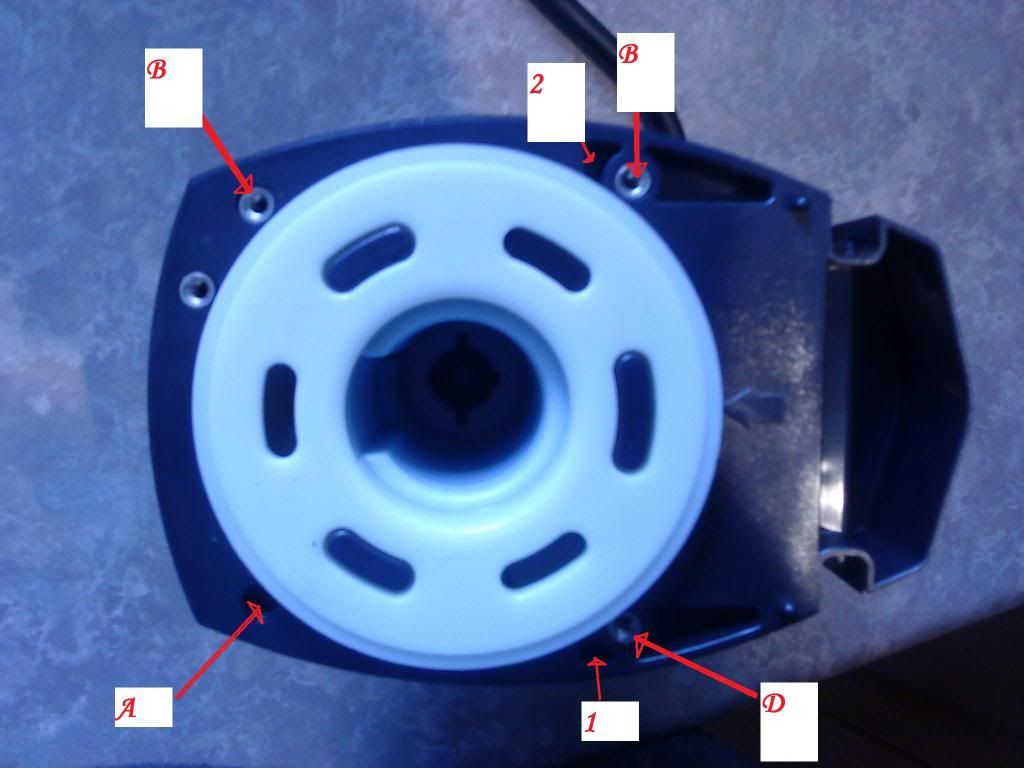

same I did with PVC glue, and it did not stuck on any, meaning there are 2 totally different materials, the 2 part epoxy was for connecting several kinds of plastic and worked fine. after grinding off the impeller blades, I put the pump on and smoothened the surface with sand paper, this way, whit the disc spinning it would become nice and balanced. as you cans se below on the picture, this is how it should have locked like, mine is nice circle from the inside, but the outside appears bit bulky.  anyhow, the reason for me to go for the pvc body was A -because this would make connections east, otherwise you always had to play around with pvc and acrylic B- the pump it selve has a kind of a disk of 1/2 inch that is still pump housing that fits in the volute, and is exact 3 1/2 inch in diameter, I have locked around and could not find a exact 3 1/2 inch inner diameter pipe, it would always be 3. 6 ore 3.7 inches the inner diameter was critical because the part of the pump that still fits in the volute has a O- seal, if it it off by 1/ 12 inch ore even less, it would not seal and leak (for a in sump model maybe not such a problem) now whit the PVC I drilled a 3 1/2 hole, which turned out to be slightly over this, so no seal, however the pvc body was so sturdy that I could put pressure on the bolds that hold the body in place, to press against the pump. I placed an O- seal (from a RODI canister) around the pump base, I angled the volute part that would connect to the pump slightly on a angle, so in fact it would press down as I fasten the bolds, as well as inwards against the pump body, making a 100% seal  A = the slight angle of the end of the volute body B= 1/2 inch air intake C= existing O- seal on the pump D= new thicker O-seal on this picture you se that the pump originally has a few slots (as the body is PVC, I gust filled them and sanded it to be smooth) ( 1 and 2)  the fastening nuts imbedded in the pump housing I removed and drilled the hole threw to the other side (now I can pass a bolt threw the volute body, threw the pump, and place a nut) (A,B,C,D) the entire pump is dead silence, only draws 60 watt of power, and delivers thons and thons of air (fine bubbles this is) |