|

|

#161

|

|||||

|

|||||

|

Does your wife sew Chad?

|

|

#162

|

|||||

|

|||||

|

Hey Chad, do you plan on leaving up the leopard print blankie? I like it. You could call it the "Sexy Tank." me-owwwwww.

oh hey! this is my 69th post. huh, go figure. Last edited by justinl; 02-15-2007 at 07:32 AM. Reason: post number what? |

|

#163

|

|||||

|

|||||

|

Quote:

I would actually like to get black sheet that reaches ceiling to floor = like what they use in photo studios... just until I develop my basement. No Ryan, Heather does not sew. Why, did you see I had the material and want something made up? That's funny 'cause you are the person that came to mind when I put it up.... whats that mean??? On a more serious note... does anyone know where I can find 45 degree elbows in 1" PVC? Rona used to have the best supply but not it seems like they have as few pieces as home depot. Maybe there isn't much of a demand anymore. - Chad

__________________

Returning to the hobby after an eight year absence. |

|

#164

|

||||

|

||||

|

I picked up some 1" 45's from the Home Depot at Glenmore last month.

|

|

#165

|

|||||

|

|||||

|

Thanks Kari. I tried HD Shawnessey, but will head up there today.

- Chad

__________________

Returning to the hobby after an eight year absence. |

|

#166

|

|||||

|

|||||

|

Quote:

Why else would you buy your underwear by the roll. |

|

#167

|

|||||

|

|||||

|

Quote:

LOL

__________________

Returning to the hobby after an eight year absence. |

|

#168

|

|||||

|

|||||

|

Well, I have almost everything I need except for a 1" union and maybe a little extra pvc pipe.

During the warm weather I put another coat of paint on the stand. I also drilled holes in the wooden tops and painted them with a marine resistant paint to try and preserve them.   Once I have all the plumbing pieces I am going to sand them down and paint them with krylon fusion. There is this little voice of reason in my head and is telling me that I shouldn't have chosen black and the color of my stand... I am usually pretty anal about keeping things clean - but I've never had to account for every single drop of spilled water before. - Chad

__________________

Returning to the hobby after an eight year absence. |

|

#169

|

|||||

|

|||||

|

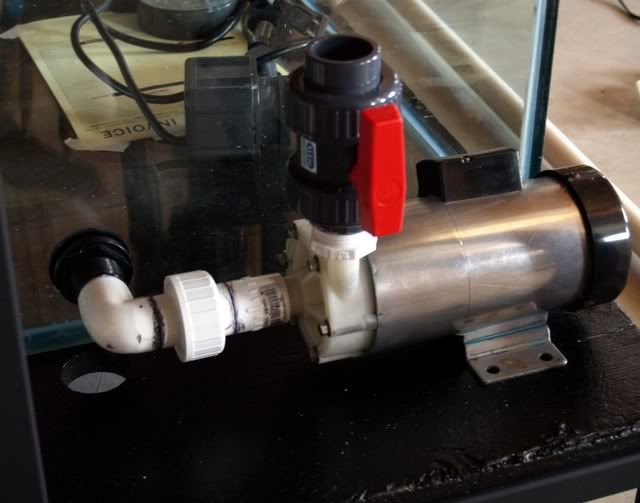

Gotta comment for a second...

Watch that plumbing for your closed loop - hard plumbing like that without any flex/vibration isolation in the plumbing - can lead to tank breakage. I snapped 2 tanks with plumbing that wasn't dissimilar to that. (and the harmonic vibrations don't help with keeping noise down) Andy

__________________

By reading, replying to, commenting about, or in any way accessing the material in this post; including but not limited to storing in a database, retrieving from a database, viewing in a web browser, including it in or making a reference to it in a legal document, or accidentally glancing at it you agree to send me $100. |

|

#170

|

|||||

|

|||||

|

Andy are you talking about the photos? The plumbing you see in the first pic is one of my return pipes and they will just hang over the top of the tank.

I do realize that I need to brace the pipe coming from the closed loop so that all that weight isn't sitting on the bulkhead. Because the glass is 1/2" thick, I'm not going to break the tank unless I really reefed on it (fortunately I have gotten in the habit of overbuilding tanks whenever there are bulkheads involved)... but a crack in that bulkhead would be equally catastrophic and would drain the tank down 2/3 of the way. Thanks, - Chad

__________________

Returning to the hobby after an eight year absence. |