|

|

#21

|

||||

|

||||

|

This is one of many permutations, it is not easy to build unless you have the proper equipment and have reasonably accurate flow factors. Size is dependent on return pump numbers, but typically most systems fit into a similar category.

Light blue is typical water level for siphon system. Dark blue is open channel. Red is safety Accepting the fact that the diameter of the red pipe is adequate enough for capacity of the return pump. |

|

#22

|

|||||

|

|||||

|

Ah I see how that would work. Certainly a compact and elegant solution. I don't know that many hobbyists would have the practical means to make that but it looks great in theory.

__________________

SPS Dedicated 24x24x20 Trimless Tank | 20 g Sump | Bubbble King Mini 160 Protein Skimmer w/ Avast Swabbie | NP Biopellets in TLF Phosban Reactor | ATI Sunpower 6 x 24W T5HO Fixture | EcoTech Vortech MP20 | Modified Tunze Nanostream 6025 | Eheim 1260 Return Pump | GHL Profilux Standalone Doser dosing B-Ionic | Steel Frame Epoxy Coated Stand with Maple Panels embedded with Neodymium Magnets "Mens sana in corpore sano" Last edited by Canadian; 11-04-2009 at 05:58 AM. |

|

#23

|

||||

|

||||

|

It works in practice too, there are many variables when it comes to flow, calculations are somewhat reliable but need to be proven, that's my next project..

|

|

#24

|

|||||

|

|||||

|

Quote:

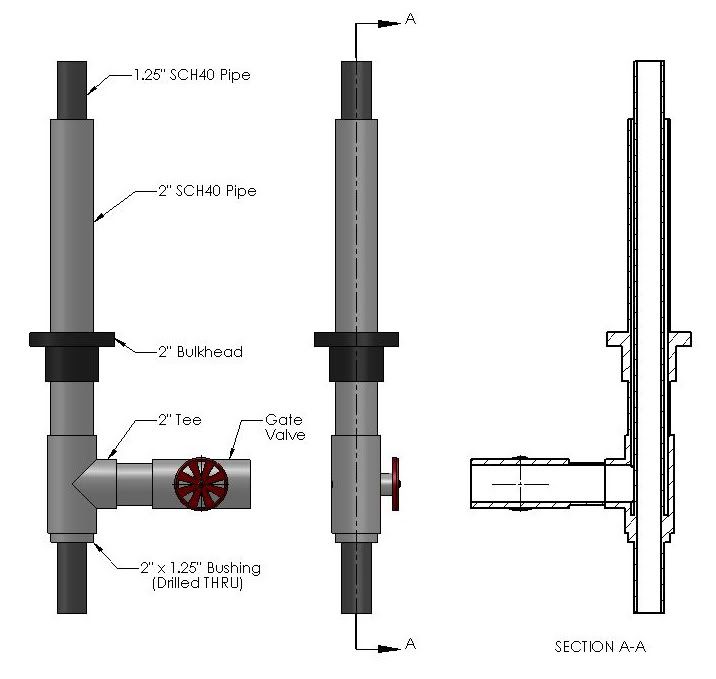

The tools required are minor and the only modification required is to the bushing which just needs the internal edge ground off so the 1.25" pipe can be slipped all the way through and glued in place. Does your design differ from this one? As far as I remember this design was really only practical if a 2" bulkhead could be used. The 2" pipe combined with a 1.25" pipe match up almost perfectly if sch40 is used. This is because the area of the 1.25" pipe slightly smaller than the area of the 2" pipe minus the space taken up by the 1.25" pipe but the larger area has more friction resulting from more surface area. Therefore the primary cannot exceed the secondary in flow meaning your limitation is simply the 1.25" pipe and you can size your return to match that. The one problem with this design is it simply isn't practical and makes very little sense to pursue it too far. The only time I have used this design is when I drilled a tank on site which had thick glass and drilling another hole would be more work and headache than introducing such a complicated design. In all other cases you're better off drilling a second hole. For example if you're planning a custom build adding the extra hole is minor and if you're not planning a custom build and you only have one drain hole chances are you won't be able to get a 2" bulkhead in there anyway. I've also done another style of a single hole herbie, it was simply a single stockman stand pipe plumbed in the usual way. the difference was that at the base of the standpipe it could rotate within a couple, a large hole was drilled in the coupling and through the pipe of the standpipe so the two holes could line up. This would add a kind of gate valve to the standpipe itself and the idea was you would be able to adjust the valve so most of the water entered the lower part of the standpipe at full siphon and only a small amount went through the top. Now this of course didn't add the security of a second drain but simply made for a quieter standpipe. Last edited by sphelps; 11-04-2009 at 05:00 PM. |

|

#25

|

||||||

|

||||||

|

Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

A typical silent, drain system in a 200 gallon tank takes up about 120 square inches and a ton of real estate and costs around $1000 I can do the same thing including a return and all the plumbing for a 1/4 of the cost and use up only 20 square inches,not using the method above but a different way .... now that's what I call practical. |

|

#26

|

||||

|

||||

|

Limiting holes in glass is always a good thing. The tank will be stronger, and there is no need for expensive and time consuming tempering. Swiss cheese bottoms add $1,000.00 to a big custom tank if you include the drilling cost, tempering, thicker glass, extra valves and related plumbing. The liability of extra holes when it comes to leaks is another consideration.

I used to follow the trend of drilling holes everywhere including the eurobrace, but now I just run the return lines over the top and hide them with rock and or aragocrete. You add a bit of friction loss, but you save a small fortune and gain peace of mind when it comes to leaking and breakage. There are some cases, such as island tanks that may require all of the plumbing to go through the bottom for aesthetic reasons. A two in one or three in one bulkhead would come in handy for these applications. |