|

|

||||||||

| Portal | PhotoPost Gallery | Register | Blogs | FAQ | Members List | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Display Modes |

|

#21

|

|||||

|

|||||

|

Quote:

|

|

#22

|

||||

|

||||

|

seeing all these nice plumbing, makes me want to rip up all my tubes and redo it, next tank i will have to use pipes for my plumbing

Quote:

__________________

riceboys 82.7 gallon sps dominant tank -concept built 3'x2'x22" full starfire tank with starfire 1 piece eurobrace and built in wave box, 1 jebao wp25, 4 mp10wes, ati led Hybrid 8 bulb fixture, csc 250 skimmer, Magdrive 18 return pump, apex lite, custom sump from concepts, biopellet reactor and carbon and gfo,bubble magnus doser and jbj ato, custom acrylic frag tank with 6 bulb t5 http://www.canreef.com/vbulletin/showthread.php?t=70851 |

|

#23

|

|||||

|

|||||

|

Thats a piece of pvc art right there , great job .

|

|

#24

|

|||||

|

|||||

|

Quote:

|

|

#25

|

|||||

|

|||||

|

Thanks! I used hard plumbing just for the looks, I don't know if there are any other advantages. My last tank was plumbed with vinyl tubing and it was perfectly functional, plus it was a lot easier to do.

|

|

#26

|

|||||

|

|||||

|

Thanks! Brought a tear to my eye haha jk.

|

|

#27

|

||||

|

||||

|

Very nice build!! Great job with plumbing... looks very nice!!

I can relate to you with the speed of the progress... I've been working on my tank for the last two months.. still in the process. I call dibs on the Kessil if you change your mind and decide to sell it! |

|

#28

|

|||||

|

|||||

|

I just received a Walz 4pi spherical PAR meter at work. This is a roughly $3000 PAR meter/sensor, and I'm excited to bring it home once the tank is filled to get some PAR readings on the Kessil. It will produce highly accurate PAR readings.

*I didn't buy this PAR meter, grant money did. It is for phytoplankton research. |

|

#29

|

|||||

|

|||||

|

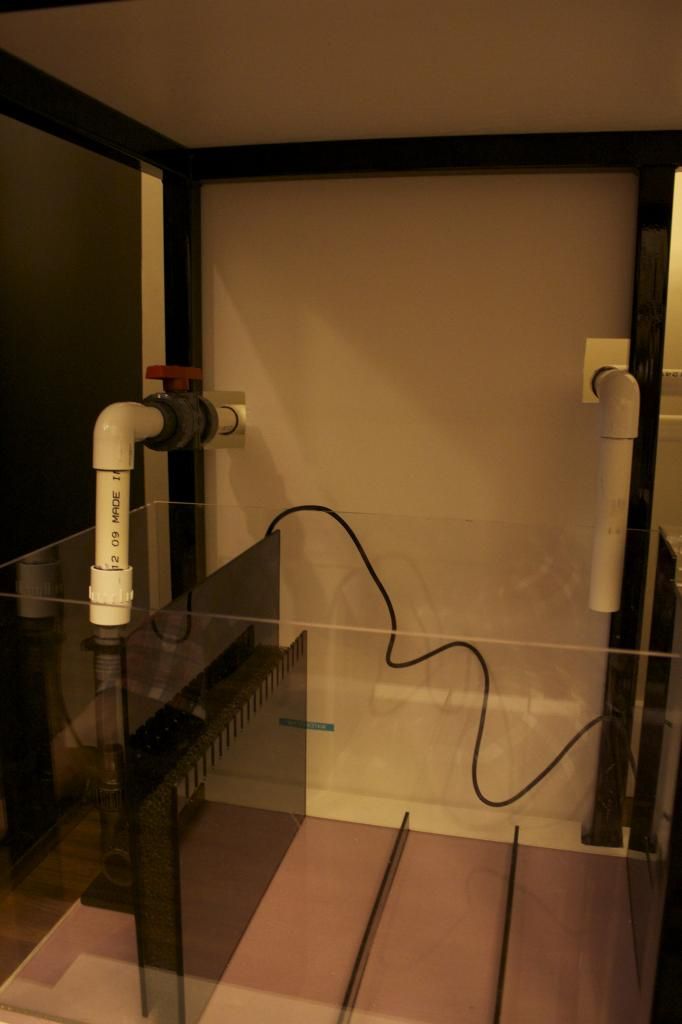

Almost ready to fill with water!

Here is a pretty detailed run down of what I did to attach panels to the back of the stand. I'm posting it because I hope it helps someone else out with their build at some point. Back panel with magnets in each corner. Slots cut out for the plumbing.  Close up of counter sunk magnet. The magnet is superglued and screwed to the panel. I got them at Lee Valley.  Acrylic disk on top of magnet.  Panel attached to the back of the stand. Plumbing is supported with hose straps on the back (not shown).  How I ended up plumbing the DC5000 pump. I would have preferred something "cleaner", but the vinyl tubing may help dampen pump noise.  The pump is sitting on top of a silicone trivet. The DC5000 actually comes with great rubber feet, and I can't even tell the difference between the pump running with and without the trivet beneath it, so I may remove it. Anyways pros/cons to using magnets: Pro: Really easy to install. Easy to change skin if you want. Inexpensive (~$2/magnet). Con: The panel has to rest on the floor. Magnets can resist pulling forces, so the panel is firmly kept upright, but the panel slides downwards until it hits the floor as the magnet does not strongly resist up/down slide forces. Thanks for reading! |

|

#30

|

|||||

|

|||||

|

Looks great! Nice and clean look to it!

Last edited by Spyd; 01-22-2013 at 03:49 PM. |

|

| Thread Tools | |

| Display Modes | |

|

|