|

|

||||||||

| Portal | PhotoPost Gallery | Register | Blogs | FAQ | Members List | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Display Modes |

|

#31

|

||||

|

||||

|

I am many things. Currently I am finishing my PhD in Chemical Engineering at UBC while also running my own company where I am designing my own products for developing countries. I also design and machine one off prototypes for the odd side job here and there when I can find time. I came from a product/transportation design background before engineering but I am starting to make the transition back as I wrap up the PhD. So in a sense, yes, I am a product designer. I realize now how much I have missed product design, so I'm trying to find a way to ride this cusp of both engineering and design backgrounds and be something pretty unique.

How about yourself? |

|

#32

|

|||||

|

|||||

|

Thats awesome, I think Vancouver really needs more people in the product design industry so the works doesnt get pushed to europe and the US.

I come from an interaction design background. Went through the school of interactive arts and technology program as SFU and came out with a passion for both interaction design and product design. In April I started a company with 4 guys I know from SFU to bring to market the Ditto 3D printer and has been going strong in that direction ever since. |

|

#33

|

|||||

|

|||||

|

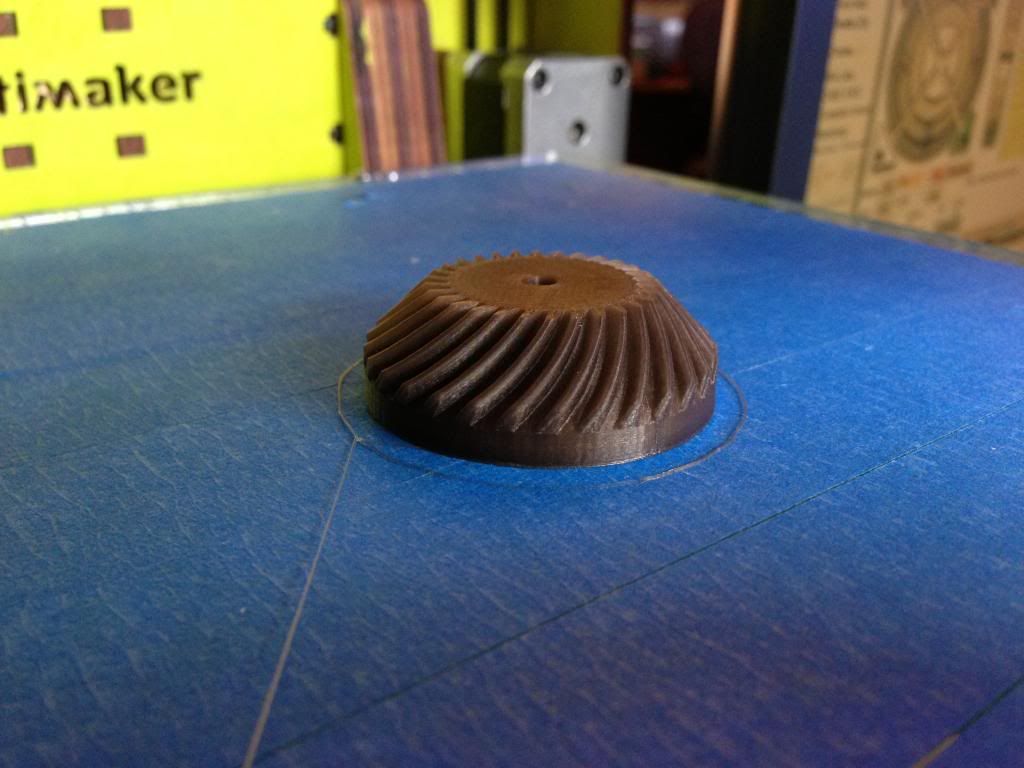

so here is a 100 micron print shot with a macro at 1:1 and f2.8. This thing is only..3cm tall, but took an hour to print

Cute Octopus by Tinkerine Studio, on Flickr and with it beside a 9.2cm bigger version that didnt take that much longer at 200 microns to print  |

|

#34

|

||||

|

||||

|

Very nice! Looks really good!

Ok, as promised... 20 micron print! Hot off the press... errr... printer. I just picked something simple and did it in translucent gold because it shows EVERY mistake. If I can make the gold look good, others are way easier. Both my camera batteries are dead so you get iphone pics ***Excuse the crazy glue on the fingers. I was re-aquascping. Here it is on the printer. No clean up needed!  In the pics you can sort of see layers, but in real life you can't see or feel them at all.  |

|

#35

|

||||

|

||||

|

Quote:

Just buggin' ya. Looks great! |

|

#36

|

|||||

|

|||||

|

Quote:

Last edited by imisky; 10-21-2012 at 07:17 AM. |

|

#37

|

|||||

|

|||||

|

Quote:

lol its always a work in progress. |

|

#38

|

||||

|

||||

|

Quote:

The bevel gear took 3 hours to print using 20 um perimeter/40 um loops and 20% rectangular infill. I could have easily dropped that to 2 to 2.5 hours but I wanted quality. I don't mind the long prints. Unlike my Huxley, I can trust my Ultimaker to print by itself for long periods of time (unless there is a ton of retraction... then I get worried). I just hit go and walk away. Most of my prints are around 10 hours. I slice with Cura. Kicks netfabb's ass. |

|

#39

|

|||||

|

|||||

|

With a provided slicing profile, 20 microns is perfectly fine. Now telling a new user, who has limited experience with a 3D printer and no profile is another story lol. Thats where majority of the failures occur.

Ive been wanting to try Cura (skeinpypy). I use skeinforge + slic3r but would appreciate the accelerated slicing of pypy on skeinforge as I like it way better over slic3r. I was wondering about netfabb as I know one of the default resolution in netfabb for UM is 0.075mm. So it should allow for a person to use it to adjust for 20 micron more easily. But again Ive never seen anyone use netfabb for slicing, only to fix broken STLS. |

|

#40

|

||||

|

||||

|

Quote:

I used slic3r and KISSlicer for a while and liked them but Cura blows them away. There are some features of the other two I wish Cura had but I could easily request the programmer (Daid) to add them. He's pretty helpful. Give Cura a go. You'll love it. |

|

| Thread Tools | |

| Display Modes | |

|

|