|

|

#31

|

|||||

|

|||||

|

Quote:

Sometimes with a 6' level like this that's hard to do, lol. Sometimes with a 6' level like this that's hard to do, lol.I will be notching the left side of the tank, kinda like mseepman has on his tank. I've phoned around everywhere local to get some 12mm glass to build the overflow box but seems like no here has anything that thick so still waiting on some prices to bring it in. Going to phone a couple places in Nanaimo today to see if my luck is a bit better. |

|

#32

|

||||

|

||||

|

If you can't find any I can cut and send some out to you

__________________

........ |

|

#33

|

|||||

|

|||||

|

hey Dap the reason for the wave action and the ATO messing around is simple. Just look at the filter socks that is what is causing it. The more crap that fills in the filter socks causes a suction on the other end. so the water is sucking from the right side cause its not flowing freely through your sock.

HTH

__________________

180 starfire front, LPS, millipora Doesn't matter how much you have been reading until you take the plunge. You don't know as much as you think. |

|

#34

|

|||||

|

|||||

|

Quote:

|

|

#35

|

|||||

|

|||||

|

Well got a bit more done. Came home tonight and thought I'd bite the bullet and start on my over flow before I chickened out and sat there looking at it for another week or two.

I really wanted to keep as much of the ABS frame as I could for strength purposes so I took a 2" hole saw and cut the plastic a bit further back then where I'll be cutting the glass. The took a Dremel with saw attachment and cut along the top of the glass from hole to hole.   So I'm really hoping that what remains of the top bracing will be enough for structural integrity. If anyone thinks I should add something to that side, speak up. Here's what's left:   The red lines represent the edge of the holes that I'll be cutting in the glass. The holes will be 1 1/2" and I'll cut a line that just touched the bottom of those 2 holes. I know that I will not want any over cut so is there something anyone can recommend that I can throw on my Dremel or something that I can finish grind that little bit of break that I'll have in the corner? |

|

#36

|

|||||

|

|||||

|

Angle grinder with a diamond blade will chew it away nicely

When I did my 180 I did this to my euro brace 1/2" glass  And cut the straight line freehand slowly with the angle grinder to get this  Now I won't lie their can be a bit of chipping but you can smother it a bit with a belt sander and water carefully Another option is to use this on a router and set a straight edge again with slow careful motion I used this when I built my 50  And got this result  I never worried about the rough edges as I covered that side with black acrylic to make overflow teeth. If you have question don't hesitate to ask

__________________

Desperately seeking serenity ... 180g custom build http://www.canreef.com/vbulletin/showthread.php?t=81400 50g custom daycare tank... http://www.canreef.com/vbulletin/showthread.php?t=65428 |

|

#37

|

|||||

|

|||||

|

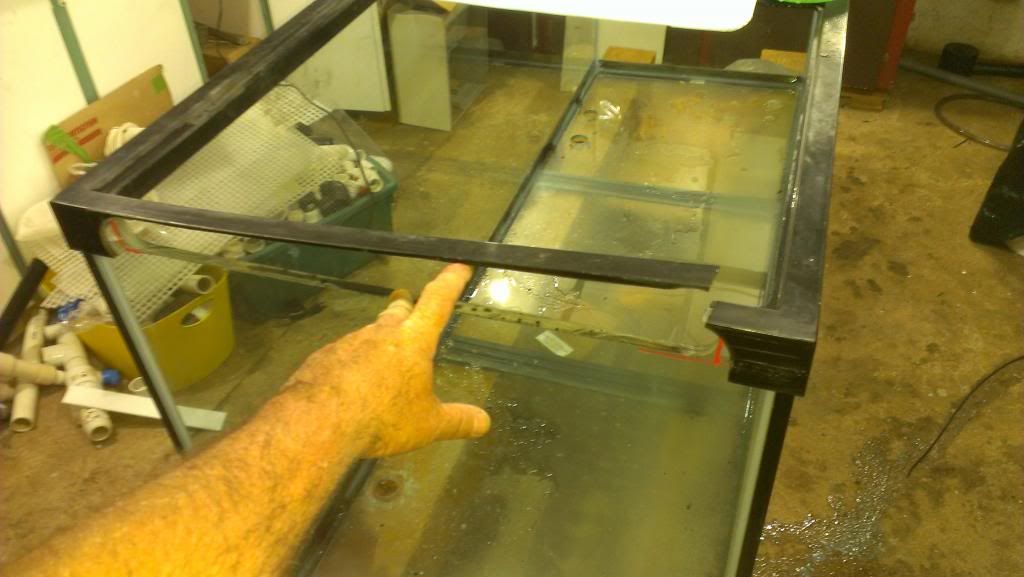

Well probably the biggest concern in this tank is DONE!!!! Some of it went well, and other.... well you'll see.

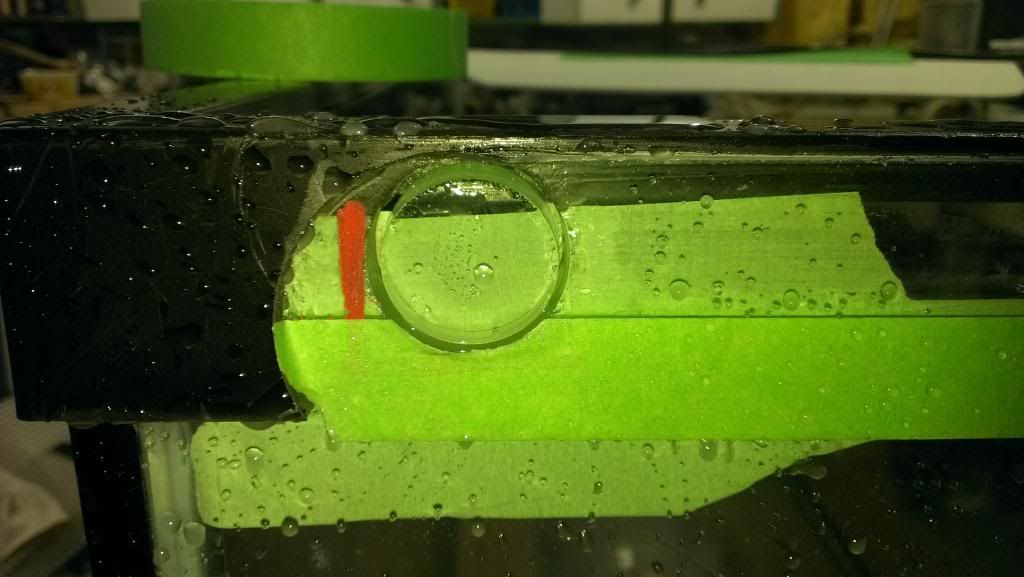

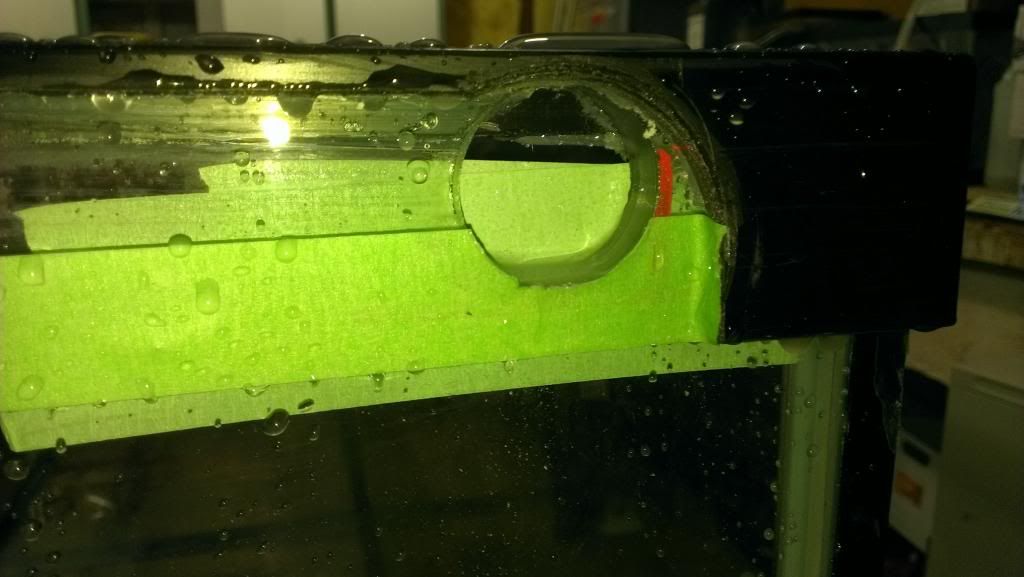

A couple months ago I was asked to do a job with these sheets of marble to do a tub surround. The sheets came 24" X 84". Well to do a 5' tub wall one of those sheets had to get cut in half and look like a factory cut. So I got me one of these:  Cut that stuff like butter, so I thought, "hey, I wonder if this would cut glass?" Does it ever  So to start I cut 2 - 1 3/8 holes. I was told to cut 1 1/2" but I didn't have one and figured an 1/8" ain't gonna make a difference. So 2 holes on either end with the wife pouring water on the bit while I drilled and presto, hole on the left:  and hole on the right:  That was the easy part. So in part to procrastinate a bit more, I prepped the side panel so the base of the saw wouldn't scratch the glass:  At this point the wife couldn't watch so she went back upstairs and turned the TV really loud. Not sure if that was to drown out the noise of the saw or so she didn't hear my screams if I screwed this up  10 min later and 30 gallons of water spray later:  And the tank:  |

|

#38

|

|||||

|

|||||

|

From there, a few cuts here, and a few cuts there, and we have a piece of glass:

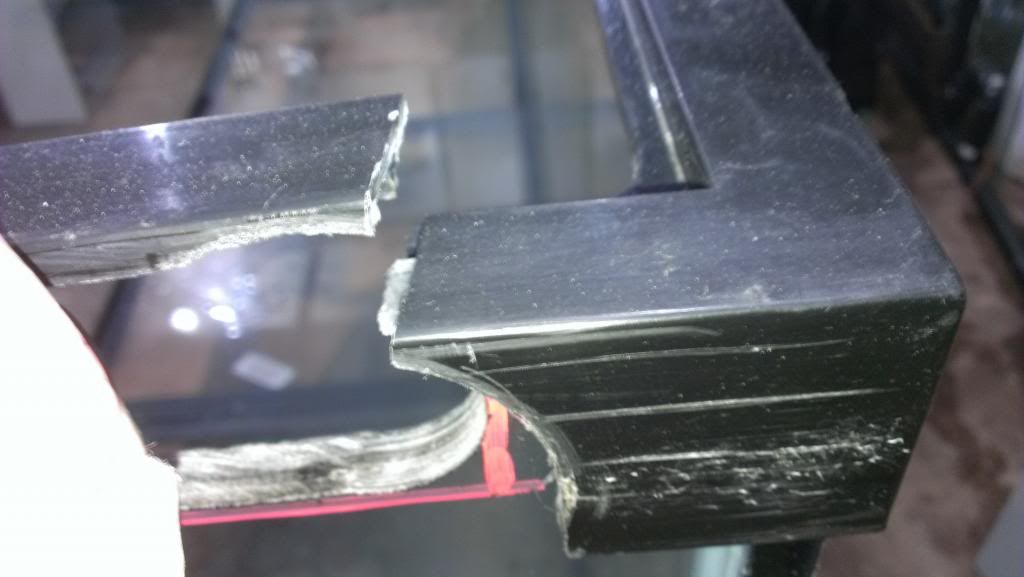

The start of the cut and end were a bit rougher than I liked so I just took a regular 1/2" drum sanding thingy for my Dremel and watered the glass down a bit and sanded the tiny rough bits off. This was the result:   But here is where things started to go awry  Just when I was feeling all proud of myself for making it this far and not have to go buy a bunch of glass to re-build the tank, I grabbed a bunch of rags to sop all the water up from inside the tank and wipe the glass down. Guess what? Did you know that when there no glass to support that trim it's really brittle  So needless to say you really shouldn't lean on it. Argh. Yup, SNAP! Du'oh!!!!!   Not sure what I should do now. Build a brace that goes over on this side? Glue an ABS sheet 24" long 2"-3" wide right on top? Pull all the bracing off and Eurobrace with glass? For some reason this option scares me a bit. I don't know. Any ideas would be greatly appreciated. Anyway when you stand back and look at it, it looks good  |

|

#39

|

|||||

|

|||||

|

that cut turned out great. i'm pretty sure they say one piece trims offer some strength while the frames that are 4 pieces glued together offer none. but i highly doubt that trim did much of anything before. you should be fine but maybe smarter people can chime in.

|

|

#40

|

||||

|

||||

|

I haven't crunched the numbers to prove it but a decade and half of engineering tells me that ABS did a whole lotta dimp for structure other than hiding someone doing a sloppy job in finishing the edges of the glass and cleaning up excess silicone. My vote would have been to remove the trim anyways. Go modern, go rimless.

|