|

|

#41

|

||||

|

||||

|

Quote:

Thanks for the input though. |

|

#42

|

|||||

|

|||||

|

Kari, have you actually had extruded crack on you? I ask because I've always built my skimmers and reactors from extruded, anywhere from 4" to 8" tubing, and as far as I know, pieces built 7 years ago are still in service. My Ca Reactor has been around for 5 years and the LFS is using one of my first skimmers built 7 years ago. I know it's not as clear, but it's always stayed crack free and not leaked. Just wondering if your experiences have been different?

__________________

Brad |

|

#43

|

|||||

|

|||||

|

brad what thickness extrudes did you use? I've used up to 1/8 extruded and it cracks like crazy (fine cracks where glue was applied)

__________________

____________ If people don't die, it wouldn't make living important. And why do we fall? So we can learn to pick ourselves up. |

|

#44

|

|||||

|

|||||

|

I've used both 1/8 and 1/4, never had anything crack. You might see some crazing around seams, but no cracks. Maybe the material these days is crappier than 5 years ago? Dunno, just always used extruded

__________________

Brad |

|

#45

|

||||

|

||||

|

Quote:

|

|

#46

|

|||||

|

|||||

|

Quote:

I never got much crazing, but all my joints were just plain old straight edges. I wonder if different suppliers have different grades? I got my tubing at a local shop, not IPP

__________________

Brad |

|

#47

|

||||

|

||||

|

There is a lot of really informative but dry reading in the tech support area at one of the acrylic manufacturers site (Cyro) for info on this subject. One would need to create a user name to get at it.

http://cyro.custhelp.com/cgi-bin/cyr...ge=std_alp.php . |

|

#48

|

||||

|

||||

|

Quote:

Richard |

|

#49

|

||||

|

||||

|

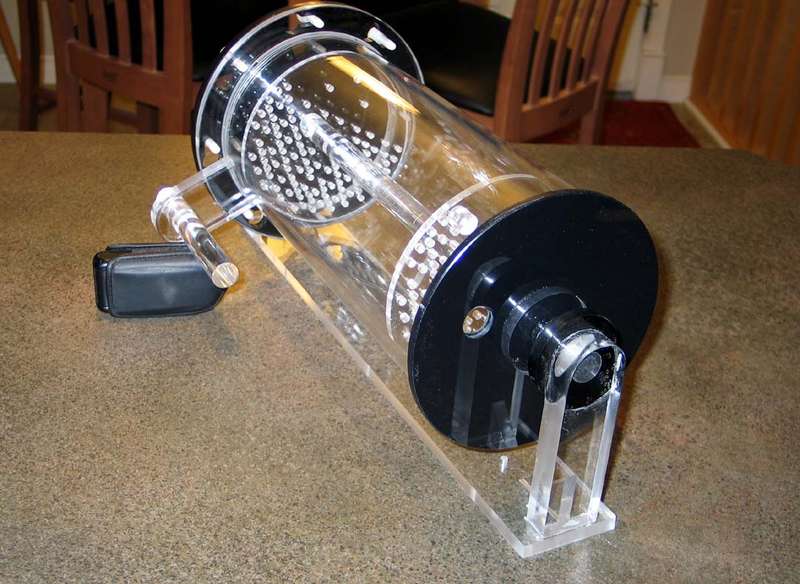

A few photos of the first. Still waiting for the cool Swivel Push To Connect Elbows. Not tested yet.

Some details, -6"OD 1/4"W cast tube -3/8" cast flanges key holed -misc 3/4" acrylic -seated o-ring seal -wall mountable vertical or horizontal -sealed unit, out of sump use -a few fittings and hoses not in photo yet See any funky stuff, let me know and I'll modify to correct. This one I beleave worked out to 3.9liters - $210    |

|

#50

|

|||||

|

|||||

|

wow! nice work

|