|

|

||||||||

| Portal | PhotoPost Gallery | Register | Blogs | FAQ | Members List | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

I recently bought a 72g bowfront and want to have it drilled. I can bring it to aquatic addictions for drilling @ $25 a hole and they will do the overflow for $45, But Dan is not that familier he said with herbie overflows. So i was hoping for some advice, I want to put in two drains to the sump, the main drain and the emergency drain. And 2 return drains? I tried googling this for hours but not many diagrams with single overflows. My question is where is the best place to have the holes to the sump drilled, in the corner or center, and should i have all 4 holes drilled the same size? I read to either get 1 1/2 inch bulkheads or do 1 inch bulkheads and use 1 1/2 piping. Is it hard to silacone your own overflow in, should i just get them to do it. I also read silicone doesnt work well with acrylic, so was wondering what one uses to attach a overflow box to the glass tank. And last does anyone have any pictures of their herbie style overflow with a single overflow i could see, or any good sites with pictures. I see alot of talking about it but not to many pictures? Any help would help :O) Hoping to drill it this weekend

Also do i need 2 returns or can i get one and just use a couple korelias for more flow in the tank Last edited by megs_clark; 08-13-2009 at 01:59 AM. |

|

#2

|

|||||

|

|||||

|

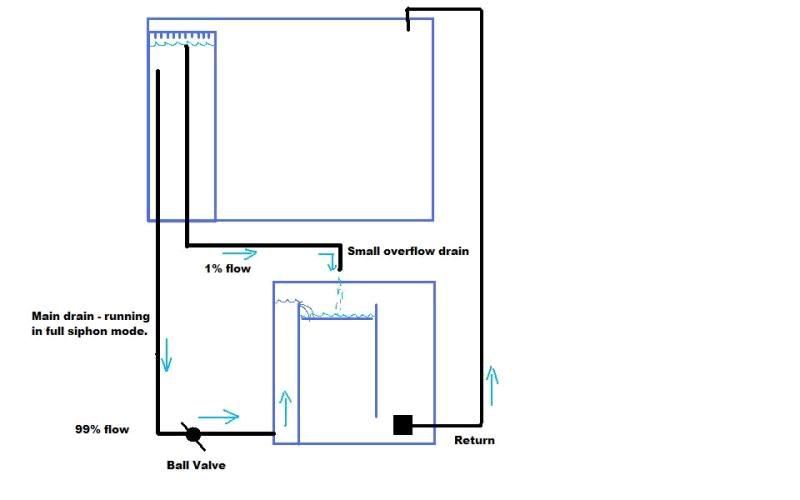

here's diagram fr rban on RC but the concept is rather simple, two holes. The Overflow chamber can be internal or external.

The diagram shows the main drain coming into the side of the sump but it doesn't have to be. Use a gate valve rather than a ball. As for drilling the sump, assume your planning an external pump. Think how you're planning on placing the return pump and laying out the sump, that will give on idea where to drill. For the overflow chamber, if internal could just have a diaginal in the corner. For the overflow, make it from glass and so you don't have to worry about the silicone not holding, can line with a thin sheet of dark acrylic. If going 1" primary drain, can flow about 600gph, 1.5" close to 1200gph and that's a fair bit for a return on a 72g. Often for additional flow within the display, people do power heads or CL.

__________________

my tank Last edited by mark; 08-13-2009 at 02:27 AM. |

|

#3

|

||||

|

||||

|

Only thing with that drawing is I would switch the ball valve out for a gate valve. Otherwise that should give you the idea.

|

|

#4

|

||||

|

||||

|

perfect, will do that and make sure i use a gate valve, thanks

|

|

#5

|

|||||

|

|||||

|

If you want a gate valve and other plumbing for unbeatable prices order from www.bulkreefsupply.com they have a great shipping policy too so you don't get surprise bills afterwards.

If I were you I would drill both drains for 1" bulkheads. They are good for 600 gph, which you wouldn't even want that much in a 72 anyway. I wouldn't drill a return, just run it up and over the edge. Since doing it this way on my 90 I doubt there will be a future that I will drill another return. Also, your return is not considered to be any sort of considerable flow. In fact, your return isn't even counted towards your turnover when discussing flow in your tank. You should have about 5-6x turnover through the sump for maximum efficiency, and low risk for microbubbles making their way to your display. You use powerheads for flow. |

|

#6

|

||||

|

||||

|

Thanks Myka, I took your advice and am on that site right now and looks great, they even have overflows lol. I was thinking if i put in a glass overflow i still need to cut the glass for the water to flow through, hmmm, not sure how to do that. Thanks for the tip on not drilling for the returns. Save me a little money that i could put toward a couple powerheads. Im torn now on just buying a bit to drill the glass ourselfs, my husband has never done it before. I thought the bits were expencive but their sure cheap on that site. Got me thinking now, lol, Myka have you ever drilled a whole, is it hard or basic, hes usualy handy like that, lol. Whats your opinion. Crazy how things add up so fast. I just want to make sure i do it right. OH one more thing their were gate valves on the site that come apart for cleaning for $30 or that are one piece ( cant take apart to clean) for $20. Will i need to take it apart to clean.

|

|

#7

|

|||||

|

|||||

|

Just a couple of additional thoughts regarding this diagram...

1) The primary drain line (the one with the ball/gate valve) is shown in this diagram to have a tall standpipe up inside the overflow box. That pipe isn't necessary. In fact, I don't think it is a good idea. Optimally, the water level in the overflow box operates at some point which is ABOVE the primary drain, yet BELOW the emergency drain. In this diagram these two drains are very close in height, providing little room to operate. Further, if there isn't enough water depth directly above the primary drain, then it tends to form a vortex and suck air down...which defeats the entire purpose of the design. 2) As I just mentioned, the diagram shows the water level at the level of the emergency overflow. That's OK, but the system works more quietly at a water level slightly below that. If you ever want to come by and look at a variety of Herbie overflows in operation, just let me know. In my refugium, I have a standpipe on the primary overflow. It is there for a very specific reason which I can demonstrate to you.

__________________

400 gal reef. Established April, 2007. 3 Sequence Dart, RM12-4 skimmer, 2 x OM4Ways, Yellow Tang, Maroon Clown (pair), Blonde Naso Tang, Vlamingi Tang, Foxface Rabbit, Unicorn Tang, 2 Pakistani Butterflies and a few coral gobies My Tank: http://www.canreef.com/vbulletin/showthread.php?t=28436 |

|

#8

|

|||||

|

|||||

|

There is a advantage to having a short standpipe on the primary in that though the Herbie method is silent, you can still get some noise from the water dropping into the overflow chamber.

This noise can be limited by lessening the drop (by raising the water level in the overflow chamber).

__________________

my tank |

|

#9

|

|||||

|

|||||

|

Another small tip regarding drilling the tank. Masking tape is a good idea, but for extra insurance place something soft below the area you're drilling just in case the tape doesn't hold. Even a piece of cardboard will do, but something a little thicker will be better to catch the 'donut' hole.

__________________

Mike 77g sumpless SW DIY 10 watt multi-chip LED build |

|

#10

|

||||

|

||||

|

Hi, Thanks for all the great advice, im just trying to track down a local drill bit (trying to get around waiting for the shipping) Seems easy to find 1 1/2 inch bits and 2" bits but can not find a 1 3/4 inch that i need for a one inch bulkhead. When i track one down i will be sure to use all your advice. Thanks for all the replys! Do you think i could drill with a 1 1/2 inch bit and use a diamond coated dremel to make it fit a 1" bulkhead? Or is that to risky

|

|

| Thread Tools | |

| Display Modes | |

|

|