At last! There is a tank!

Kevin and some guys were at the house today installing it. Wish I could have been there to document it (it's HUGE!), but I stopped in to take some pics this afternoon.

Dining room side

Office side

Overflows

Now, there's one problem that may or may not be major, and I'm hoping someone here can give me guidance. Kevin is headed out of town for the next 10 days and I don't think I'm going to be able to reach him, and they are literally putting the panel on the office side that will seal the tank in to the wall as we speak. After that, they will be mudding, taping, and tying the drywall in to the enclosure's corners, so removing the tank if this is a problem is going to become exponentially more destructive, expensive and time consuming, so I need to know if this is a problem now.

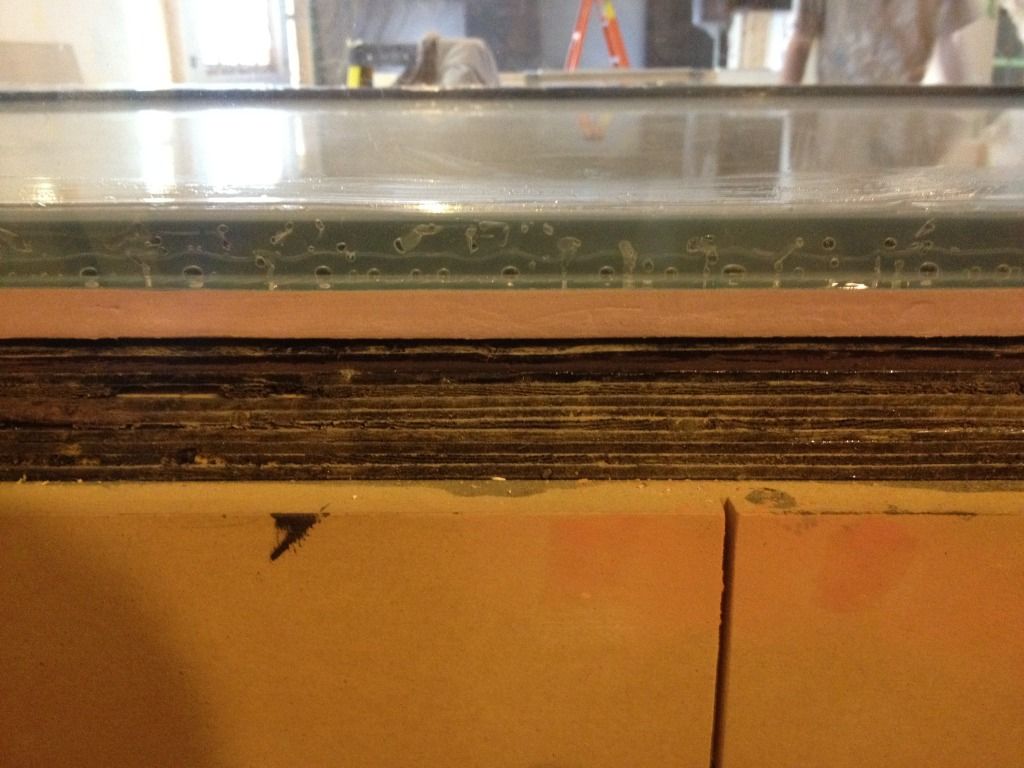

The plywood that the tank is sitting on is 3 inches thick, they had to build it up so that the cabinet framing had something other than the steel stand to attach to. When they made the plywood, it was bowed and the centre was higher than the sides, so they installed bracing on the underside to pull the plywood flat. It appeared to have worked, but now that the tank is on, I can see that there's like a quarter inch variance in height from the centre of the stand to the left and right sides. On the right side (when looking from the office), you can see all the way under the tank to the dining room.

Here's a pic of the foam/plywood interface in the centre of the tank:

Here's a pic of the foam plywood interface at the left edge (when looking from the office):

So my question is thus - how much allowance is there in that foam for compression? Will it compress enough to compensate for the slight bow in the plywood, or am I going to be looking at a snapped tank when I fill it with water? I really could use some guidance...