This is going to be the largest build I have ever been a part of (LED wise). There were a number of challenges. First of all, WEIGHT. This many LED's needed some serious heatsink action to bleed off the heat produced by this many diodes.

We went with 6 x 23" x 7" Heatsinks to control the heat. This will quite adequately cool this many LED's (with some extra fans) but moutning them was a bit daunting. This much Aluminum is fairly heavy and to further complicate things, the wiring was going to span across multiple heatsinks. We had to attach them in pairs for the wiring to work for "left to right" style dimming.

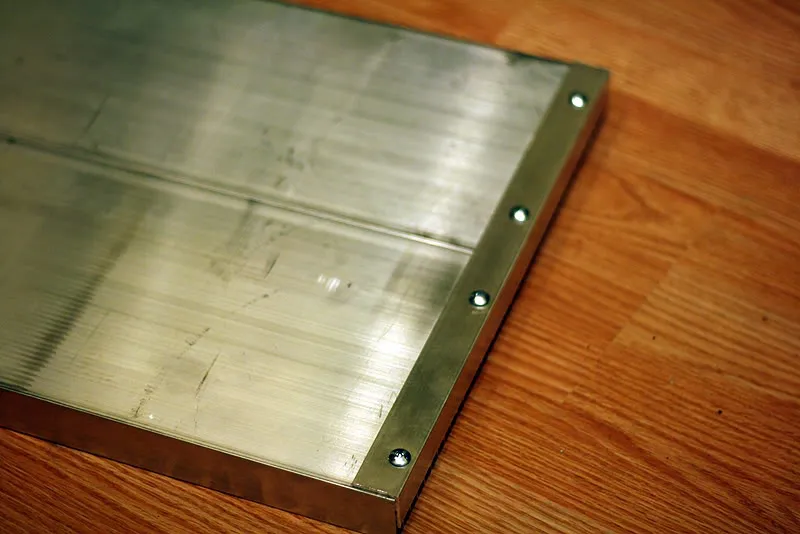

I decided to use Angle Anluminum to anchor the two together. I drilled 4 holes per heatsink and used self tapping metal screws to attach the angle aluminum to the ends. This actually proved to be fairly difficult choosing the right sized pilot hole for the screws. After a few turns through the thick aluminum the screws would start to bind. Third times a charm apparently and I was able to sink them in nice and tight.

I have to mention this right off the bat. Whenever possible, when drilling aluminum this thick, use a drill press. It can be very difficult to keep the drill steady enough to drill through 3/8" of aluminum.

Here is the bracket/angle aluminmum installed after several attempts. Sunk nice and tight to the heatsinks this prevents them from wiggling around and puttin tension on the wiring (to be installed later today).

And the first pendant is ready for LED's. This is the first of three I am building today. My plan is to finish one completely, so I can iron out any bugs for the remaining two before commiting.

.