So, this update has been a long time in coming. I'd like to blame the weather and doing summery things outside but looking outside right now I guess that can't be the only reason.

Boo cold weather.

This update itself is also a bit late because I uploaded pictures to facebook first, then meant to upload them to a Shaw photoshare I use so I could update this thread but the Shaw photoshare won't let me upload pictures. I put in a support ticket 2 days ago and haven't heard back since. I think they've forgotten or don't really care. Anyhow, Picasa to the rescue for now.

So where to begin the actual update? For the most part, progress has been steady, but slower than I would have liked. I am learning that I chronically underestimate how much effort a task will be. The drywall is up, the ceiling is up, all the mudding and painting has been done and the room trim is mostly done.

I understand now why paint stores seldom recommend high gloss paint. It shows EVERYTHING. I had those walls so smoooth I could not see ANY blemish after it was primed. And then after the finish coat I could see every seam, every screw hole, every scratch that was filled in. Crazy. It's took a while and several attempts to get it to not look too terrible on close inspection.

I also continue to hate metal stud framing for walls. Hate with a passion. I thought that perhaps once the drywall was up, it would stiffen the walls up. I was wrong. On the finished wall I can press in and get at least 1/2" flex in the middle. Man am I not happy about that. For the rest of the basement I will have to either reframe it with wood or at least use 2x3's and double up the framing before drywalling.

The other reason you want to preblock with wood is that if you want to attach things like floorboard with nails, there isn't a nail in the world that can grab that metal framing. So you have glue the floorboard on instead. Putting everything I could think of against the floorboards as the glue set still wasn't enough, they bowed out some in places so I had to use paintable caulking to fill the gaps.

It's a learning experience.

I just wish I could stop learning and start applying more. Oh well. On to the pictures!

Here we are at the doorway looking in. As you can see the drywall is up, tiles around the sink area, and the ceiling dropdown is finally finished up. It's actually painted plywood up there instead of drywall to work with the tight tolerances.

A closeup of the sink work area. There is a 2x8 under the drywall to hold the RO/DI up. It's one solid mounting. Too bad that AS was I mounting it, it slipped and landed on the TDS meter. The canisters help up luckily but the TDS meter is toast. I haven't replaced it yet but did at least buy the replacement (you can see it in the bag still on the little shelf thing).

There might have been a few swear words uttered as this played out.

I had to cut the drain pipe out and redo the whole dang thing to allow the sink to sit flush against the drywall. Again, more swear words.

A look towards the tank from the back of the room. Where I'm standing will eventually house the 110g cube which at this point I'm thinking of keeping for a little while as I'm considering not moving my eel and butterflies into the 280g. The butterflies are too destructive; and the eel is not appreciating the company of his tank mates these days. I can only feed him at night when the rest are sleeping or in the morning before I go to work and the lights haven't turned on yet.

Anyhow you can see the light rails are back up and the plumbing is started.

Around the tank is painted plywood, the rest of the room is drywall. Where the two meet I covered the seam with a corner moulding seen here.

As you can see I still am storing some stuff in the tanks. Ignore the bags in the sump for the time being. They hold stuff which will come into play at a later date. In the meantime here is the plumbing return started. 2" flex PVC to the intake of the Dart, 1.5" flex after that. The hugeness of the 2" tru-union ball valve made it hard for me to visualize how I wanted the plumbing to be but I think I'm happy with this arrangement. I would have preferred not to put a 90 in the intake line but otherwise it would have jutted into the room by a large margin. My old 75g had its pump like this and it ran for like 7 years so I'm hoping it will be OK.

This is the manifold that feeds various outlets. Up goes to the 280g, to the right will go to the frag tank (which will be the 40g semi-cube - 24x24x12 - that right now houses my carpets and clowns. They'll move into the big tank and that will free up that tank for this). The frag tank feed will be a 1" line which right now isn't installed - it will just glue into the valve when I'm closer to working on that part.

The other two outlets are for a 1/4" line (just for the heck of it - but it might be useful for drip acclimations) and another outlet that's just capped for now - it's there in case I ever want to run another line to somewhere down the road.

A look at the delivery manifold loop. 4 3/4" locline outlets, two at the front and two at the rear and two 3/4" outlets (capped off for now) in case I ever want more down the road.

The Herbie overflow. A wet test will tell me if I need to shorten the pipes.

Tight tolerance for the 2" gate valve on the overflow but you can get to it easily enough and adjust it.

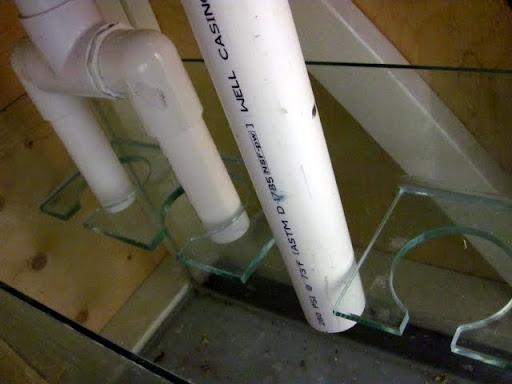

The emergency overflow pipe seen here.

Another look at the overflows draining into the sump.

A shout out of thanks to reefcanada for the sock holders. I'm not convinced I'll be happy with the 4" socks but man the glass sock holders are just so damned sexy.

A look under the skirt, er, stand. Here is the span at the back of the tank. There is a 2x8 and a 2x6 glued-n-screwed together supported at the ends with 3 vertical 2x4's each. I am hoping this will hold up and not bow in. I couldn't detect any bowing when I had the tank filled last, so hopefully it's OK.