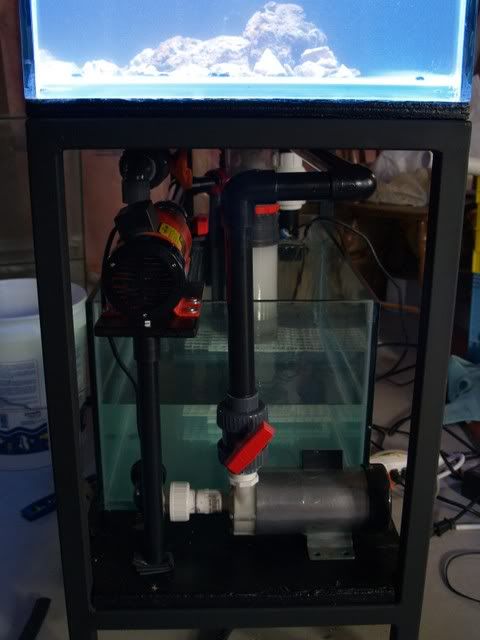

Here is a photo of the system now that I have it all up and running:

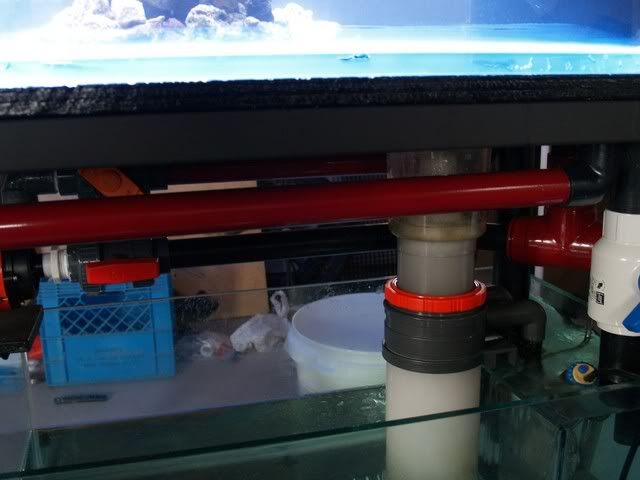

Fortunately there are no vibrations that I can detect with my hand coming from the sump return pump... I think it is lucky that I looked a little harder and paid a little extra for the Japanese-motored Iwaki. Now the system is far from silent, the fans from both pumps are very noticeable... each one probably twice as loud as that fan in your computer - and maybe a higher pitched hum. I know there are some that strive for a slent sysytem but this isn't a problem for me - my nano design was all about downplaying and hiding equipment; however, this setup is about displaying and showcasing the equipment... bringing attention to all of the hardware and power it takes to maintain a single drop of ocean so far from its natural environment. Speaking of showcasing equipment, here are a few shots of the plumbing:

There are a couple things about the setup that I would do differently if I had the chance. First of all I would make my skimmer chamber shorter so the water didn't have so far to fall. Secondly, I think my disconnect unions are too close to the effluent sides of the pumps - when they are wide open, I get a rattling sound in there that I think is cavitation due to the water going from the impeller (3/4" passage) and straight into the over-sized chamber (over 1") inside the unions. I have found that by closing the ball valve partway (probably closer to 3/4") I can eliminate the sound without decreasing output. I think if the over-sized unions were further from the pumps there wouldn't be a problem. The plumbing is enlarged to 1" in order to reduce friction and reduce the velocity from the return pipes - which is good because I have ran the head-loss calculator with my actual measurements and the total came to 1468gph of flow from both pumps. That makes an even 40x's turnover. (I said that the plumbing was 1" and then sized down to 3/4" at the pumps but actually my intake to the closed loop starts out at 1.5" to allow for a larger bulkhead screen that's less prone to plugging. It then goes down to 1" and then to 3/4" at the pump).

One last pic:

Hope you like,

- Chad